litho printing Explained: A Walkthrough for Beginners

A Comprehensive Overview to Comprehending Litho Printing Methods

The globe of litho printing, a strategy originating from the late 18th century, is an interesting mix of background, development, scientific research and art. Stay with us as we journey into the fascinating world of litho printing.

The Historical Advancement of Litho Printing

The historic trajectory of litho printing, an essential technology in the realm of communication, is an exciting tale of human resourcefulness. Birthed in the late 18th century by Alois Senefelder, this method was originally an economical approach of publishing staged jobs. Lithography, stemmed from the Greek words for 'stone' and 'to write', used a smooth rock surface area to move photos onto paper. The process developed with the arrival of the rotary press, which substantially enhanced productivity (litho printing). In the 20th century, the development of countered lithography changed the market, permitting automation of high-quality prints. Each phase of litho printing's development showcases mankind's relentless quest of performance and high quality in visual interaction.

Translating the Scientific Research Behind Litho Printing Inks

Progressing in the exploration of litho printing techniques, the focus now shifts to the scientific research behind litho printing inks. The structure of these inks, their drying out procedure, and shade mixing methods create the backbone of this intricate art kind. Comprehending these elements is important to grasping the craft and attaining the desired print outcomes.

Composition of Litho Inks

In lithographic printing, the essential function of litho inks can not be overstated. The structure of litho inks varies relying on its purpose, yet generally, they consist of two major elements - automobiles and pigments. Pigments, the color-providing elements, are carefully ground particles suspended in the vehicle, a liquid that brings the pigment onto the printing surface. The automobile is an intricate combination of materials, oils, and solvents, which affect the ink's drying out time, bond, and gloss. In addition, different additives exist to boost specific properties like circulation, drying, and resistance to ecological impacts. Each element plays a vital part in the last print's high quality, making the exact formulation of litho inks a complex science.

Ink Drying Process

From the structure of litho inks, attention transforms to the interesting procedure of ink drying out. 2 key approaches are made use of in litho printing: oxidative drying out and absorption. Absorption, on the other hand, entails the ink permeating into the paper fibers, which is a faster process but can lead to less vivid colors.

Shade Mixing Strategies

While the drying out procedure plays a crucial duty in litho printing, the science of visit the site shade blending techniques holds equal relevance. The science behind litho printing inks also takes right into account the transparency of the ink, which impacts how shades overlay and mix.

The Art and Style Elements in Litho Printing

Litho printing breathes life into art and design via its unique elements. Litho printing fits a selection of shades, allowing musicians to create vivid and dynamic prints. This mix of accuracy and convenience makes litho printing a favored selection for lots of musicians and developers.

Modern Applications of Litho Printing Methods

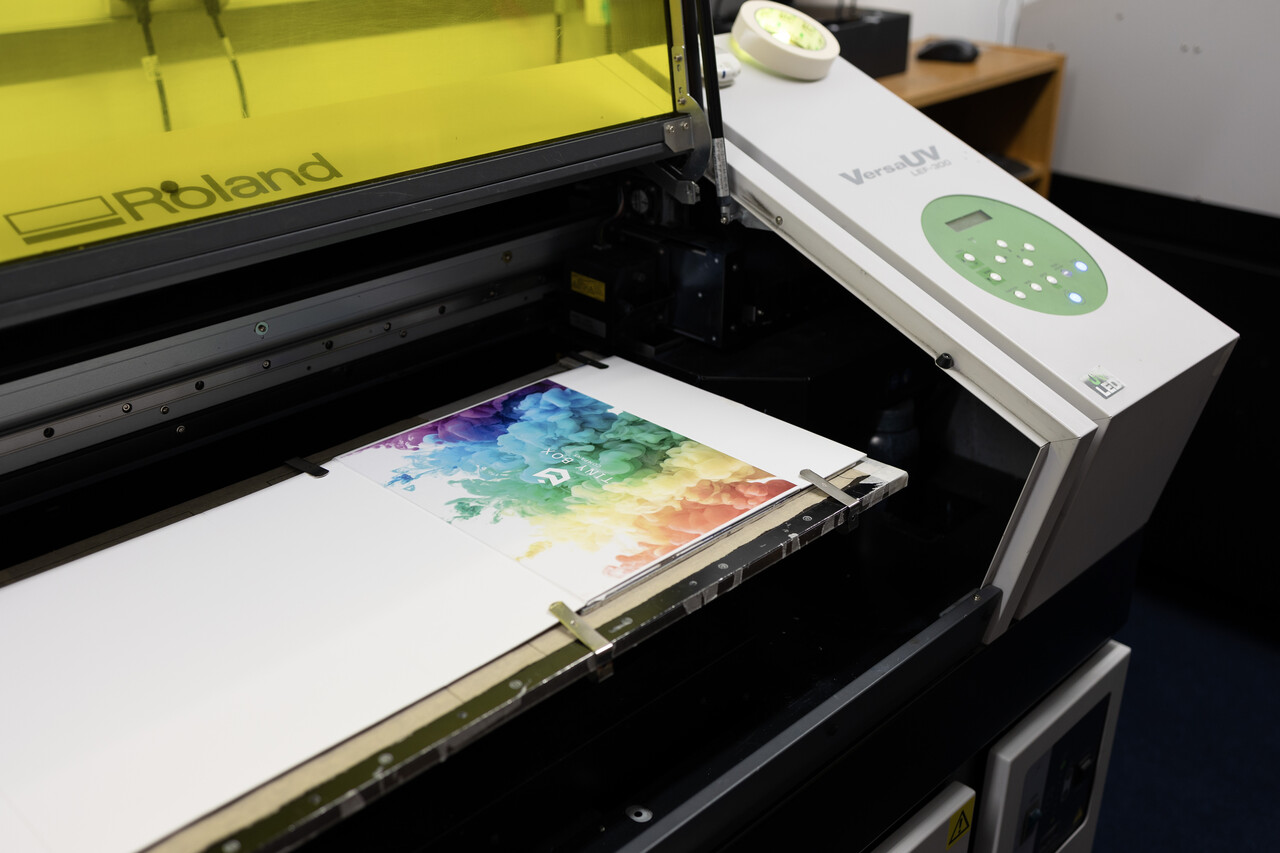

Litho printing strategies have located extensive usage in the modern industrial field. Its impact and importance continue to expand with the development of new advancements and modern technologies in the field. This section will certainly discover these contemporary applications and the transformative function they play in the printing market.

Commercial Litho Printing Utilizes

Litho printing stays a crucial component of the commercial industry. High-volume printing tasks, such as the manufacturing of books, newspapers, and packaging, count on litho printing for its ability to provide exceptional picture high quality and expense performance. Litho printing likewise offers a wide color range, remarkable to that of digital printing.

Advancements in Litho Printing

Pressing the limits of standard strategies, modern innovations have fueled a host of innovations in litho printing. One famous development is electronic litho printing, which combines the virtues of electronic modern technology with litho's high-grade result. These technologies emphasize her comment is here the enduring relevance of litho printing in the modern globe.

Checking out the Process of Litho Printing: Step by Step

Obstacles and Solutions in Contemporary Litho Printing

In spite of the accuracy and custom that litho printing proudly promotes, it is not without its collection of contemporary difficulties. Digital litho printing permits for cost-effective brief runs and simple modification, dealing with the issue of variable data. Therefore, while there are difficulties, the litho printing market is proactively adjusting to satisfy them head-on, guaranteeing its relevance in the future.

Verdict

In verdict, litho printing, with its abundant history and clinical details, holds a significant location in the print market. The future of litho printing pivots on its capacity to adapt to these changing demands, affirming its enduring worth in an evolving market.